DEPARTMENT OF MECHANICAL ENGINEERING

Home || Laboratories || CENTERS

About Centre for Materials and Manufacturing (CMM)

The Centre for Materials and Manufacturing (CMM) is a unique excellence an interdisciplinary institute which combines research in fields of physics, chemistry, physical metallurgy and applied mathematics to provide an understanding of material properties and processing. The center focuses on applied research and industry-relevant education aiding local economy. The center offers assistance to scholars in their pursuit of research and applied projects.

Dr Pankaj Kumar

Laboratory In-Charge

Vision

The Centre for Materials and Manufacturing (CMM) is a unique excellence an interdisciplinary institute which combines research in fields of physics, chemistry, physical metallurgy and applied mathematics to provide an understanding of material properties and processing. The center focuses on applied research and industry-relevant education aiding local economy. The center offers assistance to scholars in their pursuit of research and applied projects.

Mission

Nurture Innovation, Creativity, Entrepreneurial Mindset, and Mechanical Engineering Knowledge in students by implementing novel educational experiences.

Develop effective instructional infrastructure and faculty resources.

Promote interdisciplinary learning and expertise in the application of Information Technology.

Contribute to community development and the growth of Mechanical Engineering through service, consultancy and research activities.

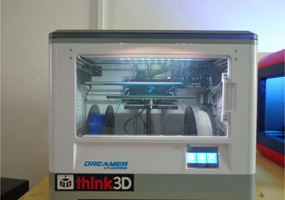

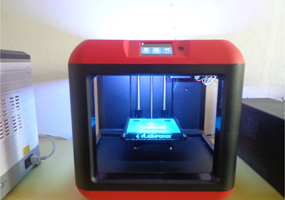

3D Dreamer

3D Printer

Thrust Areas

- Nano materials Additive manufacturing

- Metals Processing Technology

- Polymer / Composite Technology

- Manufacturing System Engineering

- Mechanical Engineering Design

- Surface Engineering

- Characterization and Testing of Materials

| S.No. | Name of the work | Development | Status |

|---|---|---|---|

| 1 | Synthesis of Fused silica material for Radome application | New material | In process(fabrication) |

| 2 | Influence of pulse and polarity variation on Keyhole tungsten arc welding (K-TIG) of Steels & Aluminum alloys | Process | In process(fabrication) |

| 3 | Synthesis of Bullet proof material | New material | In process(Literature) |

| 4 | Preparation and characterization of vegetable based cutting fluids | Process | Preparation and characterization completed |